Natural Sources of Black Food Coloring

How do you make black food coloring – The pursuit of natural food coloring often leads down unexpected paths, a journey as rich and layered as the hues themselves. While artificial blacks are readily available, the quest for naturally derived shades opens a world of subtle variations and intriguing processes. This exploration delves into the methods of extracting black food coloring from various sources, revealing the artistry and challenges inherent in this culinary pursuit.

Activated Charcoal as a Black Food Coloring Source, How do you make black food coloring

Activated charcoal, a finely powdered form of carbon, offers a deep, intense black hue. Its creation involves heating organic matter, like coconut shells or wood, in a controlled environment to create a highly porous material. This porosity is key to its ability to absorb impurities and contribute its rich black color to food. To use it as a food coloring, simply add a small amount of activated charcoal powder to your desired food item, stirring gently to avoid clumping.

The intensity of the black color will depend on the amount added and the nature of the food. Remember, activated charcoal can affect the taste slightly, imparting a subtle earthy undertone. Careful experimentation is advised to achieve the desired color and flavor balance.

Burnt Sugar for Black Food Coloring

The alchemy of caramelization transforms simple sugar into a rich, dark, almost black coloring. This process involves heating sugar slowly over low heat, constantly stirring, until it melts and gradually darkens. The transformation is mesmerizing, the sugar shifting from translucent gold to amber, then a deep mahogany, and finally, a near-black hue. This burnt sugar syrup can be added to various foods, imparting not only color but also a distinct caramel flavor.

The key to success lies in careful control of the heat and constant monitoring to prevent burning. Overheating can result in a bitter taste, compromising the overall flavor profile.

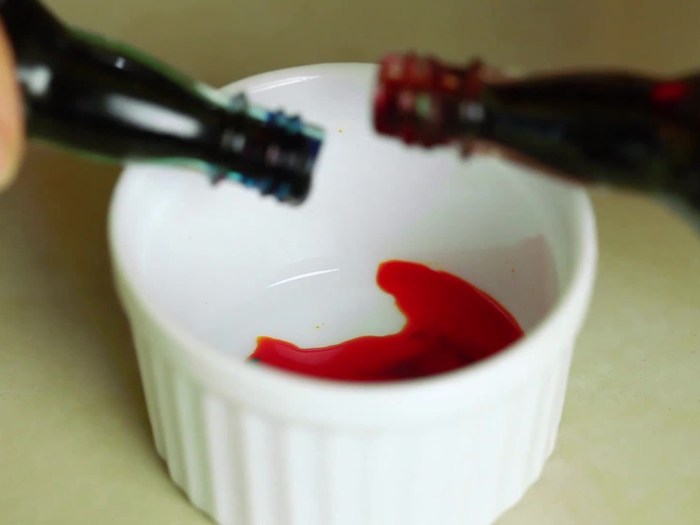

Creating black food coloring often involves combining several colors, such as red, blue, and yellow, to achieve a deep, true black. However, the type of coloring you use impacts the final result; for instance, if you’re working with oil-based products, you might consider using oil based food coloring for a richer, more vibrant black in applications like cake decorating.

The intensity of the black will depend on the specific oil-based dyes you select and the ratios used.

Blackberry and Other Dark-Fruited Sources for Black Food Coloring

Blackberries, elderberries, and even deeply colored plums offer a gentler approach to natural black food coloring. The process involves extracting the juice from the fruits. This can be achieved by simmering the berries in a small amount of water, then straining the mixture to separate the pulp from the juice. The resulting juice, rich in anthocyanins, provides a deep purple-black color.

However, the intensity and stability of the color can vary significantly depending on the fruit and the extraction method.

| Source | Preparation Method | Color Intensity | Stability |

|---|---|---|---|

| Blackberries | Simmering and straining | Medium-low | Low (fades with light and heat) |

| Elderberries | Simmering and straining | Medium | Medium (more stable than blackberries) |

| Plums (dark varieties) | Simmering and straining | Low-medium | Low (sensitive to oxidation) |

| Activated Charcoal | Direct addition | High | High (relatively stable) |

Challenges and Limitations of Natural Black Food Colorings

While the allure of natural black food colorings is undeniable, certain challenges must be acknowledged. The intensity of color from natural sources is often less vibrant and less consistent than commercially produced alternatives. Furthermore, the stability of the color can be affected by factors such as light exposure, temperature fluctuations, and the pH of the food. Natural black colorings are also more prone to fading or discoloration over time.

The subtle nuances in flavor imparted by these natural colorings may also not always be desirable in every application. The preparation methods themselves can be time-consuming, demanding patience and precision.

Commercial Black Food Coloring

The vibrant hues of our culinary creations often rely on the subtle magic of food coloring. While natural sources offer a certain charm, the intensity and consistency demanded by modern food production frequently necessitate the use of commercial alternatives. These synthetic black food colorings, manufactured for a range of applications, present a fascinating blend of chemistry, regulation, and consumer choice.

Understanding their composition, safety, and practical applications allows for informed decisions in both professional and home kitchens.Commercial black food colorings are not a monolithic entity. Rather, they exist in various forms, each with its own properties and advantages. The differences are not merely aesthetic; they impact how the color is used, the final result, and even the overall cost.

Comparison of Commercial Black Food Colorings

Liquid, powder, and gel forms dominate the market. Liquid black food coloring, often found in small bottles, is convenient for quick additions to batters and glazes. Its ease of use is balanced by a potentially lower pigment concentration compared to other forms. Powdered black food coloring, on the other hand, offers greater intensity and often a longer shelf life.

The need for precise mixing can be a slight drawback, requiring careful attention to prevent clumping. Finally, gel food colorings provide the most concentrated pigment, making them ideal for achieving deep, rich blacks, particularly in applications where a large volume of liquid might dilute the color. The intense pigmentation allows for a small amount to achieve a desired effect.

Chemical Composition of Common Black Food Colorings

The precise chemical composition can vary depending on the manufacturer and specific product. However, common components include carbon-based pigments, often derived from synthetic sources. These pigments, designed for food-grade use, undergo rigorous testing to ensure their safety. Commonly used are variations of carbon black, a fine black powder created through the incomplete combustion of hydrocarbons. Specific additives might include stabilizers and dispersants to improve the color’s solubility, consistency, and shelf life.

It’s important to note that the precise chemical breakdown is often proprietary information, protected by manufacturers.

Safety Regulations and Certifications for Black Food Colorings

Food safety regulations vary across different jurisdictions, but all adhere to a fundamental principle: to ensure that food colorings are safe for human consumption. In many countries, including the United States and the European Union, black food colorings must undergo stringent testing and meet specific purity standards before they can be commercially used. Certifications, such as those issued by relevant food safety agencies, verify that the product meets these requirements.

Consumers can look for these certifications on packaging to ensure compliance with safety regulations. These certifications help build trust and ensure that the coloring agents meet safety and purity standards.

Cost-Effectiveness and Application Methods of Commercial Black Food Colorings

The cost and application methods of commercial black food coloring vary significantly depending on the type, brand, and quantity purchased. Generally, larger quantities are more cost-effective per unit. Below is a table comparing some representative examples. Note that prices are subject to change based on location and retailer.

| Brand | Type | Price (Approximate) | Application |

|---|---|---|---|

| Brand A | Liquid | $5 | Easy to mix into liquids, suitable for batters and icings. |

| Brand B | Powder | $7 | Requires thorough mixing, ideal for achieving intense black in baked goods and fondant. |

| Brand C | Gel | $10 | Highly concentrated, small amount needed, perfect for intricate designs and intense color in small areas. |

| Brand D | Powder (Bulk) | $25 | Cost-effective for large-scale production, suitable for industrial use. |

Storage and Shelf Life of Black Food Coloring: How Do You Make Black Food Coloring

The longevity and vibrancy of your black food coloring, whether derived from natural sources like activated charcoal or meticulously crafted in a commercial laboratory, hinges entirely on its storage. Improper handling can lead to a rapid decline in quality, resulting in a dull, lifeless hue or, worse, a compromised product. Understanding the nuances of storage and shelf life is crucial for any serious baker or culinary artist.Proper storage significantly impacts the shelf life of black food coloring.

Both natural and commercial varieties require specific conditions to maintain their potency and prevent degradation. Factors such as light exposure, temperature fluctuations, and air exposure all play a role in determining how long your coloring remains usable.

Factors Affecting Shelf Life

Several environmental factors contribute to the deterioration of black food coloring. Exposure to direct sunlight, for instance, can cause the pigments to fade and break down, resulting in a less intense color. Similarly, extreme temperatures, both high and low, can accelerate the degradation process. High temperatures can promote microbial growth, particularly in natural colorings, while freezing can cause the separation of components and a loss of color intensity.

Finally, prolonged exposure to air can lead to oxidation, altering the chemical composition of the coloring and affecting its stability. Imagine a bottle of vibrant black food coloring left open on a sunny windowsill; its fate is sealed, a slow descent into a murky, less-than-desirable shade. Properly sealed containers, stored in cool, dark places, will significantly extend the usable life.

Signs of Spoiled or Degraded Black Food Coloring

Recognizing the signs of spoiled or degraded black food coloring is crucial to avoid compromising the quality of your culinary creations. A significant change in color, such as a noticeable fading or a shift towards a brownish or muddy hue, is a clear indicator of degradation. A change in texture, such as thickening, clumping, or the appearance of mold (especially in natural colorings), is another telltale sign.

Finally, an unpleasant odor, which can be musty, sour, or otherwise off-putting, signals that the coloring has likely spoiled and should be discarded. Consider a batch of homemade black sesame seed paste, carefully prepared and stored; if a moldy smell emanates from the jar, it is time for a replacement.

Determining Expiration Date and Optimal Usage Period

Establishing a definitive expiration date for black food coloring can be challenging, as it varies significantly depending on the source and the storage conditions. Commercial black food colorings often have a printed “best before” date, but this is a guideline, not an absolute cutoff. Natural black food colorings, on the other hand, usually lack such clear indicators. For both types, a prudent approach is to rely on sensory evaluation.

Regularly inspect the coloring for changes in color, texture, or odor. If any of these signs of degradation are observed, discard the product immediately, regardless of the “best before” date. A conservative approach would be to use commercial black food coloring within six months to a year of purchase, provided it’s stored correctly. For natural black food coloring, like that made from black sesame seeds, a usage period of a few weeks to a couple of months, under optimal storage conditions, is more realistic.

The shelf life of natural colorings is intrinsically shorter due to the absence of preservatives often found in commercial versions.

Question Bank

Can I use black food coloring in savory dishes?

Yes, but use sparingly as the intense color can overpower subtle flavors. Test in small amounts first.

How long does homemade black food coloring last?

Homemade colorings, especially natural ones, have a shorter shelf life. Store in airtight containers in the refrigerator and use within a week to 10 days for best results.

Will black food coloring stain my equipment?

Yes, it can. Use dedicated equipment or thoroughly clean any utensils immediately after use.

Are all black food colorings vegan?

Not necessarily. Check the ingredient list for any animal-derived components.

Where can I buy high-quality black food coloring?

Specialty baking supply stores or online retailers often carry a wider selection of high-quality options.