Methods for Incorporating Food Coloring into Epoxy

Can you color epoxy with food coloring – Successfully incorporating food coloring into epoxy resin requires careful consideration of the coloring agent’s form and the mixing technique employed. The final color and clarity of the epoxy project depend heavily on the proper dispersion of the pigment. This section details effective methods for achieving vibrant and consistent results.

Mixing Liquid Food Coloring into Epoxy Resin

Mixing liquid food coloring into epoxy resin is a straightforward method, particularly suitable for smaller projects. Begin by thoroughly mixing the epoxy resin and hardener according to the manufacturer’s instructions. This ensures a uniform chemical base for the colorant. Then, add a small amount of liquid food coloring to the mixed epoxy, starting with less than you think you’ll need.

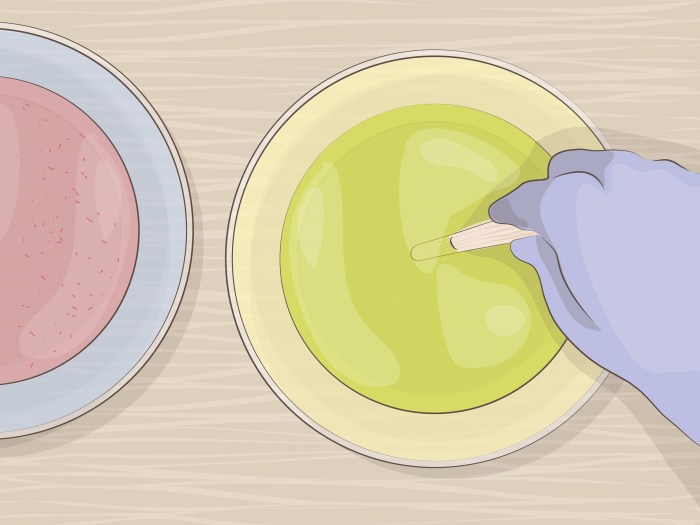

Stir gently but thoroughly using a clean, non-porous utensil such as a plastic stick or toothpick, avoiding the introduction of air bubbles. Continue adding colorant incrementally until the desired shade is achieved. Remember to always work in a well-ventilated area. It is advisable to conduct a small test batch to gauge the color intensity before committing to the full project.

Dispersing Powdered Food Coloring in Epoxy Resin

Powdered food coloring requires a more meticulous approach to avoid clumping and ensure even distribution. First, thoroughly mix the epoxy resin and hardener as directed by the manufacturer. Then, in a separate container, gently combine a small amount of the powdered food coloring with a tiny amount of the epoxy mixture. This creates a paste-like consistency, preventing the powder from clumping when added to the larger batch.

Gradually incorporate this paste into the remaining epoxy, stirring continuously with a clean utensil to ensure complete dispersion. For larger quantities, using a low-speed mixer may assist in achieving a smoother, more uniform color. Again, a test batch is highly recommended to refine the color and ensure even distribution.

Achieving Even Color Distribution in Larger Epoxy Projects, Can you color epoxy with food coloring

For larger epoxy projects, achieving uniform color distribution is crucial. Pre-mixing the colorant with a small portion of the epoxy before incorporating it into the main batch helps to prevent streaking and color variations. Gentle and continuous stirring, potentially with the aid of a low-speed mixer, is essential. For very large projects, consider dividing the epoxy into smaller batches and mixing the colorant into each separately to ensure consistency.

Pouring the colored epoxy into the mold in layers, allowing each layer to cure slightly before adding the next, can also help prevent settling or color separation.

Yo, so you wanna know if you can dye epoxy with food coloring? Totally doable, but the results can be kinda unpredictable. Think about how it interacts with liquids – check out this article on oil water food coloring to get a better idea of how different liquids behave. Understanding that will help you predict how your food coloring will mix with the epoxy resin and give you better control over the final color.

Basically, experiment carefully and you’ll get rad results!

Comparison of Liquid, Gel, and Powdered Food Coloring Methods

The choice between liquid, gel, and powdered food coloring depends on the specific project and desired outcome. Each method presents advantages and disadvantages:

- Liquid Food Coloring:

- Advantages: Easy to mix, readily available.

- Disadvantages: Can sometimes result in less vibrant colors, may slightly reduce the epoxy’s clarity.

- Gel Food Coloring:

- Advantages: Highly concentrated, produces vibrant colors, less likely to affect epoxy clarity.

- Disadvantages: Can be more expensive than liquid options, requires careful measurement to avoid overly intense color.

- Powdered Food Coloring:

- Advantages: Highly concentrated, produces intense colors, can create unique effects (e.g., metallic finishes).

- Disadvantages: Requires careful mixing to avoid clumping, can be messy.

Factors Affecting Color Results

Achieving the desired color in epoxy resin projects using food coloring requires careful consideration of several factors. The final hue is not simply a matter of adding dye; the properties of both the epoxy resin and the coloring agent, as well as their interaction, significantly influence the outcome. Understanding these factors is crucial for consistent and predictable results.Epoxy resin type significantly impacts color development.

Different resin systems possess varying degrees of transparency and viscosity. A clear epoxy will yield brighter, more saturated colors compared to a cloudy or amber-tinted resin. The viscosity also affects the dispersion of the food coloring; thicker resins may require more thorough mixing to prevent streaking or uneven color distribution. For instance, a slow-curing epoxy might allow for better pigment dispersion, leading to a more uniform color, while a fast-curing epoxy may require more rapid and vigorous mixing.

Epoxy Resin Type and Color Outcome

The chemical composition of the epoxy resin influences its interaction with the food coloring. Some resins may react differently with certain dyes, leading to variations in color intensity or even unexpected color shifts. For example, a resin with a slightly yellow tint might subtly alter the perceived hue of a blue food coloring, resulting in a greenish-blue instead of a pure blue.

This interaction is not always predictable and may require experimentation to determine the optimal resin for a specific color. Manufacturers’ data sheets may provide some guidance on the resin’s transparency and compatibility with dyes, though testing is often necessary.

Color Fading and Discoloration

Exposure to ultraviolet (UV) light is a major factor contributing to color fading and discoloration over time. Food coloring, especially those derived from natural sources, are often less lightfast than commercial epoxy pigments. To mitigate this, consider using UV-resistant epoxy resins or adding a UV-resistant clear coat to protect the colored epoxy from sunlight. Furthermore, the storage environment also plays a role; prolonged exposure to high temperatures or humidity can accelerate color degradation.

For example, an epoxy project displayed in direct sunlight for extended periods may exhibit noticeable fading within months, whereas a project kept indoors in a shaded area may retain its color for much longer.

Food Coloring to Epoxy Ratio and Color Intensity

The ratio of food coloring to epoxy directly impacts the intensity and saturation of the final color. A higher concentration of food coloring generally leads to a more vibrant and opaque color. However, excessive amounts of food coloring can also lead to a less uniform mixture, possibly causing uneven color distribution or even a grainy texture. Conversely, a low concentration will result in a paler, more translucent color.

Finding the optimal ratio often involves experimentation; starting with a small amount of food coloring and gradually increasing it until the desired intensity is achieved is a recommended approach.

Color Shade Variation with Food Coloring Amount

| Food Coloring Amount (drops per oz of epoxy) | Resulting Shade | Opacity | Vibrancy |

|---|---|---|---|

| 1-2 | Pale, translucent | Low | Low |

| 3-5 | Light, semi-translucent | Medium-low | Medium |

| 6-8 | Medium, semi-opaque | Medium | High |

| 9-12 | Deep, opaque | High | Very High |

FAQ Compilation: Can You Color Epoxy With Food Coloring

Is it safe to use food coloring in epoxy resin intended for food contact?

No. Food coloring is not designed for use in epoxy intended for food contact. Use only epoxy resins specifically certified for food-safe applications.

Can I use expired food coloring in epoxy?

While it might still work, expired food coloring may have reduced intensity or altered consistency, potentially affecting the final color and curing process. It’s best to use fresh food coloring.

How long does the color last in epoxy?

The longevity of the color depends on the type of food coloring, epoxy resin, and UV exposure. Some colors may fade over time, especially with prolonged sunlight exposure. UV-resistant epoxy resins can help mitigate this.

What happens if I add too much food coloring?

Adding excessive food coloring can lead to uneven color distribution, altered curing times, and a less vibrant final color. Start with small amounts and gradually increase until you achieve the desired shade.