Types of Color Test Pages: Color Test Page Print

Color test page print – Choosing the right color test page is crucial for ensuring accurate color reproduction in any printing project. Different printing methods and color spaces demand specific test pages to guarantee consistency and quality. Understanding the nuances of these pages is key to avoiding costly reprints and frustrating discrepancies between digital and printed output.

Color test pages are not a one-size-fits-all solution. The type you need depends heavily on the printing process, the color space you’re working with, and whether you’re focusing on proofing or calibration. This means carefully considering your project’s specific requirements before selecting a test page.

Color Test Page Comparison

The following table compares common types of color test pages, highlighting their strengths and weaknesses for various applications.

| Color Space | Typical Uses | Advantages | Disadvantages |

|---|---|---|---|

| CMYK | Offset printing, most print media | Industry standard for print; widely understood and used; allows for accurate color matching within the CMYK gamut. | Limited color gamut compared to RGB; can be challenging to accurately predict final output due to variations in inks and substrates. |

| RGB | Digital displays, web design, soft proofing | Wide color gamut; ideal for screen-based workflows; allows for visualization of colors outside the CMYK gamut. | Not directly applicable to print; colors will often appear different when printed using CMYK. |

| Pantone | Specific brand colors, high-end printing | Precise color matching; allows for consistent reproduction of specific colors across different printing methods. | Limited color range; can be expensive; requires specialized inks and printing processes. |

Color Test Pages for Different Printing Processes

The design and content of color test pages should be tailored to the specific printing method. Different processes have varying characteristics that affect color reproduction.

For offset printing, a CMYK color test page with a range of color patches, grayscale steps, and density controls is essential. This allows for the assessment of ink density, dot gain, and overall color accuracy. An example would be a test page incorporating the standard ISO coated v2 or uncoated v2 color charts.

Digital printing often utilizes a similar CMYK test page, but it may also include additional tests related to specific printer characteristics, such as registration and toner consistency. Pages designed for digital presses often focus on achieving consistent color across a wide range of media types.

Screen printing requires a test page focused on spot colors, often using Pantone or other spot color systems. This is because screen printing typically uses separate inks for each color, rather than a CMYK process.

Proofing vs. Calibration Test Pages

The purpose of a color test page dictates its design. Proofing and calibration serve distinct goals.

Proofing test pages aim to provide a visual representation of the final printed output. They focus on accurately depicting the color and tonal range of the project. These pages are generally used to review and approve color before mass production begins. They usually feature a selection of colors representative of the project and may include a visual representation of the intended substrate.

Calibration test pages, on the other hand, are designed to adjust the color settings of a printing device. They contain precise color patches and grayscale steps used to measure and correct color imbalances. These pages are crucial for maintaining consistent color across multiple print runs and ensuring that the printer is outputting colors accurately according to a defined profile.

Creating a Color Test Page

So, you’re ready to dive into the world of color accuracy and need a reliable test page? Creating your own is easier than you think, especially using a vector graphics editor like Adobe Illustrator or Inkscape. These programs offer precise control over color and allow for easy adjustments. Let’s get started!Creating a basic color test page involves a straightforward process.

First, you’ll define the size and orientation of your page. Then, the real fun begins: adding your color swatches and gradients.

Adding Color Swatches and Gradients

To add color swatches, simply create individual shapes (squares or circles work best) and fill them with your desired colors using the editor’s color picker. For precise control, use color codes (like hex codes or CMYK values) to ensure consistency. Label each swatch clearly with its corresponding color code and name for easy reference. Adding gradients is just as simple; create shapes and apply linear or radial gradients using the gradient tool.

Again, be sure to clearly label each gradient with its starting and ending colors and type (linear or radial). Experiment with different gradient angles and color combinations to create a comprehensive test.

Essential Elements of a Comprehensive Color Test Page

A truly comprehensive color test page goes beyond just a few random swatches. It needs to include a range of colors and color types to thoroughly test your printing or display capabilities. Consider including these essential elements:

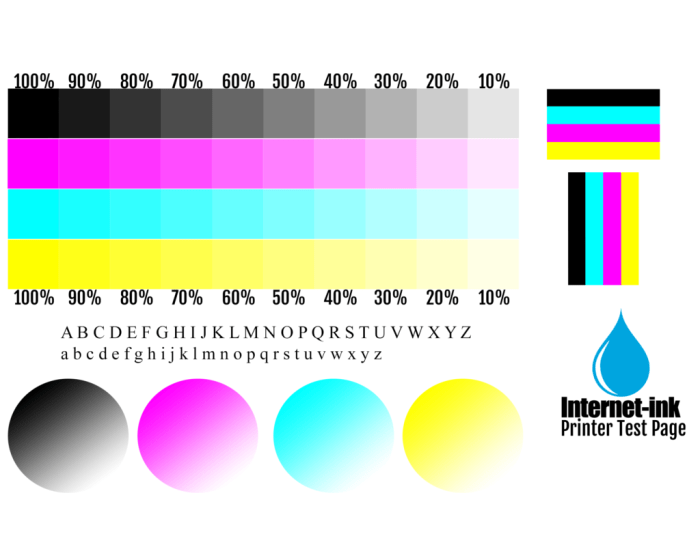

- Solid Color Swatches: A wide array of colors spanning the color spectrum, including both bright and muted tones. Aim for a diverse selection representing various color families (reds, blues, greens, yellows, etc.).

- Gradients: Various linear and radial gradients, showcasing smooth transitions between colors. Include both simple two-color gradients and more complex multi-color gradients.

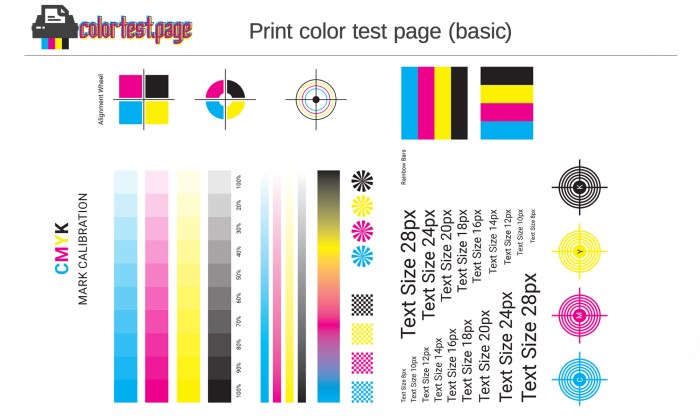

- Process Colors (CMYK): Include swatches of standard process colors (cyan, magenta, yellow, and black) to test their reproduction accuracy.

- Spot Colors (Pantone): If you’re working with spot colors, include swatches of these as well. This is crucial for accurate representation of brand colors or specific color requirements.

- Grayscale: A series of grayscale swatches ranging from pure black to pure white, demonstrating the range of gray tones achievable.

- Color Combinations: Include examples of color combinations commonly used in your work to test how they interact in print or on screen. This could be pairs of complementary colors, analogous colors, or triadic color schemes.

Organizing Color Test Page Elements

Layout is key to creating a usable color test page. A well-organized page ensures easy comparison and identification of colors. Imagine a grid-based layout. The top section could showcase solid color swatches arranged systematically, perhaps by color family (reds in one column, blues in another, and so on). Below that, you could place your gradients, organized by type (linear, radial) and perhaps color scheme.

Finally, at the bottom, include your grayscale and spot color swatches. Each swatch should be clearly labeled with its color name and corresponding color code (hex, CMYK, Pantone, etc.) directly beneath it. Maintaining consistent spacing between swatches will ensure a clean and readable layout. The overall aesthetic should be simple and uncluttered, prioritizing clarity and easy comparison of colors.

Interpreting Results from a Color Test Page

Okay, so you’ve printed your color test page – now what? Interpreting the results is key to understanding how accurately your printer is reproducing colors. This involves comparing the printed colors to the intended colors and identifying any discrepancies. This process helps you fine-tune your printer settings and achieve consistent, accurate color reproduction.Analyzing a color test page involves a visual comparison of the printed swatches with the expected colors.

Look for obvious shifts in hue, saturation, and lightness (or value). For instance, a vibrant red that prints as a dull brownish-red indicates a problem with either the red ink, the printer’s calibration, or both. Similarly, a light blue that appears significantly darker suggests an issue with the cyan ink density or overall color balance. Pay close attention to subtle variations across the page; even small inconsistencies can signal a larger problem.

Color Shift Identification and Inconsistencies

Identifying color shifts involves a careful visual inspection of each color patch on the test page. You should compare the printed colors to a reference, ideally a digital version of the same color profile used for printing. Look for differences in hue (the color itself), saturation (the intensity or purity of the color), and brightness (the lightness or darkness of the color).

Significant deviations from the reference indicate a color shift. Inconsistencies appear as variations in color across multiple prints of the same test page or uneven color distribution within a single patch. For example, a gradual darkening of a color from one side of a patch to another points to an issue with ink distribution or printer head alignment.

Assessing Color Reproduction Accuracy Across Printing Methods, Color test page print

Comparing results from different printing methods (e.g., inkjet, laser, offset) highlights the unique challenges each presents in color reproduction. Using the same color test page across these methods allows for a direct comparison. For example, an inkjet printer might struggle with the accurate reproduction of deep blacks, while a laser printer might have difficulties with smooth color gradients. Offset printing, with its inherent process complexities, might exhibit different color shifts entirely.

By noting these differences, you can choose the most appropriate method for specific color-critical projects and understand the limitations of each. A consistent methodology for evaluating the results – perhaps using a colorimeter or spectrophotometer for objective measurements – is crucial for accurate comparison.

Comparing CMYK and Spot Color Test Page Interpretations

CMYK test pages assess the accuracy of the four process colors (cyan, magenta, yellow, and key/black) used in most digital printing. Spot color test pages, conversely, evaluate the reproduction of specific pre-mixed inks. Interpreting a CMYK test page involves assessing the accuracy of individual colors and their combinations. Spot color interpretation is simpler, focusing on whether each spot color prints as intended.

A CMYK page might show subtle variations in color across a gradient, indicating issues with ink blending or printer calibration. A spot color page, however, will show either an accurate match or a clear mismatch to the expected color. The choice of which test page to use depends on the project; CMYK for most digital work and spot color when specific ink formulations are essential.

Troubleshooting Color Issues Using a Color Test Page

Color test pages are invaluable tools for identifying and resolving discrepancies between your digital design and the final printed output. By analyzing the results of a properly executed test print, you can pinpoint the source of color problems and take corrective action. This section will guide you through common issues, their causes, and practical solutions.

Common Color Problems Revealed by Color Test Pages

Color test pages often highlight several recurring problems. These discrepancies can significantly impact the final aesthetic quality of your print job. Understanding these common issues is the first step towards effective troubleshooting.

Potential Causes of Color Discrepancies

Various factors can contribute to inaccurate color reproduction in print. These range from issues with your printer settings and color profiles to problems with the print media itself. Identifying the root cause is crucial for implementing the correct solution. Understanding the potential sources of error helps in developing a targeted troubleshooting strategy.

Troubleshooting Guide for Common Color Issues

Let’s address some common color problems and provide step-by-step solutions based on what a color test page reveals.

1. Issue

Noticeable banding in color gradients. This appears as distinct horizontal stripes of color instead of a smooth transition.

2. Potential Cause

This often results from insufficient ink or improper ink distribution by the printer. It can also be due to low-resolution images or incorrect printer driver settings.

3. Solution

First, check your printer’s ink levels and replace any low cartridges. Then, ensure the print head is clean and properly functioning. If the problem persists, try increasing the image resolution or adjusting the printer driver settings to prioritize smoother color transitions. You may need to experiment with different print quality settings.

4. Issue

Color Casts (e.g., a noticeable overall yellow, blue, or magenta tint). The printed colors appear consistently off from the intended hues.

5. Potential Cause

This could stem from an incorrectly configured color profile, inaccurate color calibration of the printer, or issues with the paper’s brightness and color temperature. The lighting conditions during proofing can also play a role.

6. Solution

Start by verifying that the correct color profile (e.g., ICC profile) is selected for both your design software and printer. If necessary, recalibrate your printer using color calibration tools. Consider testing with different paper types to see if the color cast is paper-related. Ensure your proofing environment has consistent lighting.

7. Issue

Misregistration – colors are not aligned correctly, leading to blurry or fringed edges where colors meet.

8. Potential Cause

This usually indicates a problem with the printer’s mechanical alignment or a potential issue with the paper feed mechanism. Sometimes, it can be a problem with the print driver settings related to color registration.

9. Solution

Consult your printer’s manual for instructions on aligning the print heads. Check for any obstructions in the paper path. If the problem persists, it might require professional servicing. Review your print driver settings to ensure correct registration options are selected.

Advanced Color Test Page Techniques

Creating truly effective color test pages goes beyond simply printing color bars. By incorporating a range of elements and understanding their interaction, you can significantly improve your color management and troubleshooting capabilities. This section delves into more sophisticated techniques for designing and utilizing color test pages.

A well-designed color test page acts as a comprehensive diagnostic tool, allowing for precise analysis of your entire color reproduction workflow. This includes evaluating the performance of your printer, monitor, and even the paper itself. The data gathered helps you identify and correct inconsistencies, ensuring accurate and consistent color across different media and devices.

Designing a Comprehensive Color Test Page

A robust color test page should include a grayscale ramp, color bars, and density patches, all strategically arranged for optimal analysis. Imagine a page divided into distinct sections. The top third features a grayscale ramp, progressing smoothly from pure white to pure black in even increments. This section helps assess the printer’s ability to reproduce neutral grays accurately, revealing any banding or inconsistencies in tone reproduction.

Below this, a series of color bars, using a standardized color space like sRGB or Adobe RGB, are arranged. These bars represent a range of hues and saturations, allowing for evaluation of color accuracy and gamut coverage. Finally, the bottom third contains density patches, small squares of varying color density within a single color. These help determine the printer’s ability to accurately reproduce different levels of ink saturation.

The layout should be clean and clearly labeled for easy interpretation.

Color Test Pages in Color Management Workflows

Color test pages are integral to effective color management. They act as a benchmark against which you can calibrate your entire workflow. By comparing the printed output of the test page to the intended digital values, you can identify discrepancies between your monitor, printer, and the final printed result. This process involves using color management profiles (ICC profiles) to translate color data between devices.

For example, you might create a profile for your monitor to ensure it accurately represents colors on screen, then use a profile for your printer to ensure consistent color output. The color test page helps verify that these profiles are correctly implemented and that the entire system is working in harmony. Regular use of color test pages helps maintain consistency and prevent costly reprints due to color inaccuracies.

Evaluating Paper Type Impact Using a Color Test Page

Different paper types significantly affect color reproduction. The paper’s brightness, texture, and absorbency all influence how inks are laid down and perceived. To evaluate this, print the same color test page on various paper stocks. By comparing the results, you can see how different paper types alter the color, density, and overall appearance of the printed output. For instance, a matte paper might absorb ink more readily, leading to slightly duller colors compared to a glossy paper.

A thicker paper stock may also result in less color bleed. This analysis allows for informed decisions when selecting paper for a specific project, ensuring that the final product accurately reflects the intended colors. Careful documentation of the paper type used alongside the printed test page is crucial for future reference and comparison.

FAQ Summary

What is the difference between a color test page for proofing and one for printer calibration?

A proofing test page verifies the accuracy of color representation before mass printing, while a calibration page fine-tunes the printer’s settings for optimal color output.

Can I create a color test page using free software?

Yes, several free and open-source vector graphics editors, such as Inkscape, allow you to create effective color test pages.

How often should I perform a color test print?

The frequency depends on factors like printer usage, ink changes, and the criticality of color accuracy in your projects. Regular testing, at least monthly or after significant changes, is recommended.

What if my color test page reveals significant color inconsistencies?

This indicates potential issues with your printer settings, ink, or even the paper type. Systematic troubleshooting, involving cleaning the printer, checking ink levels, and recalibrating, is crucial. If the problem persists, consider seeking professional assistance.